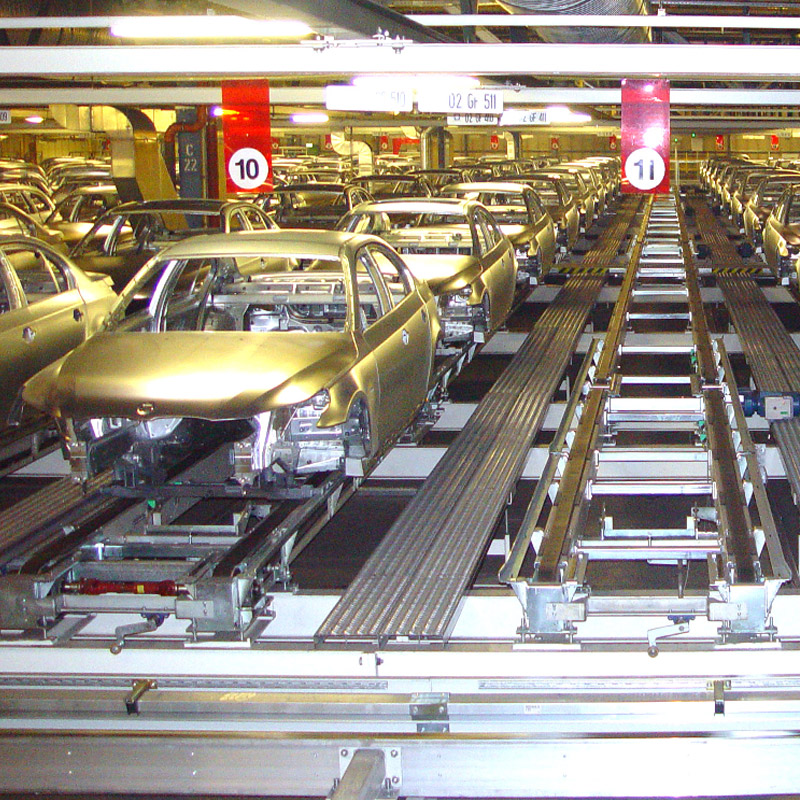

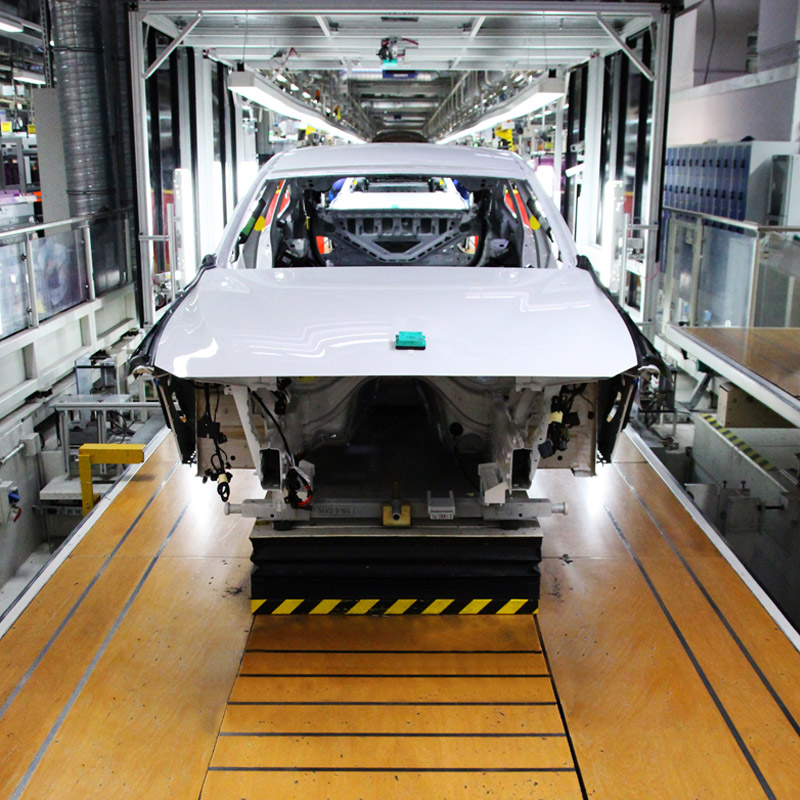

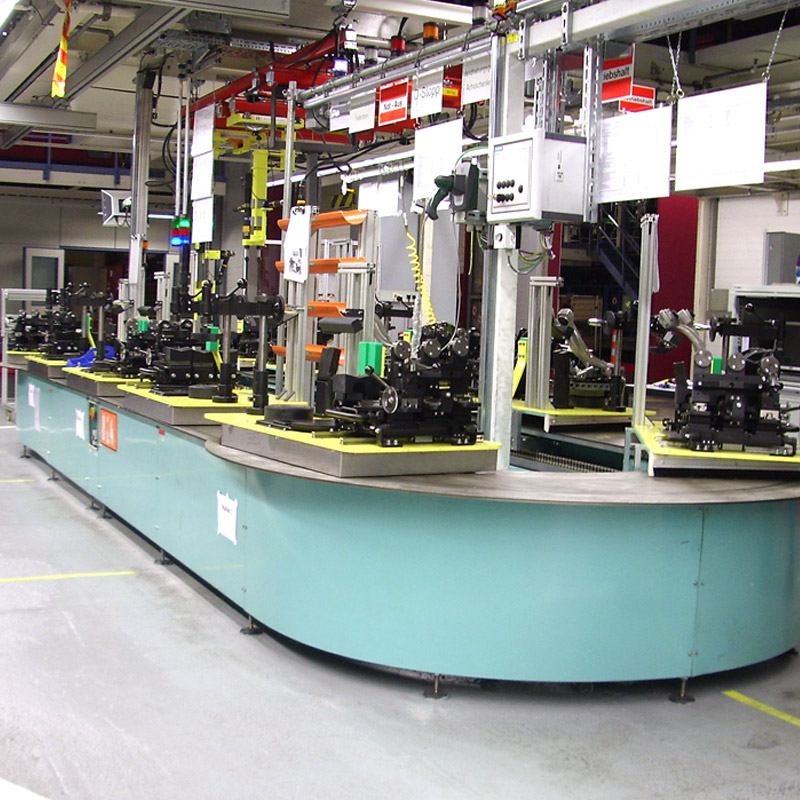

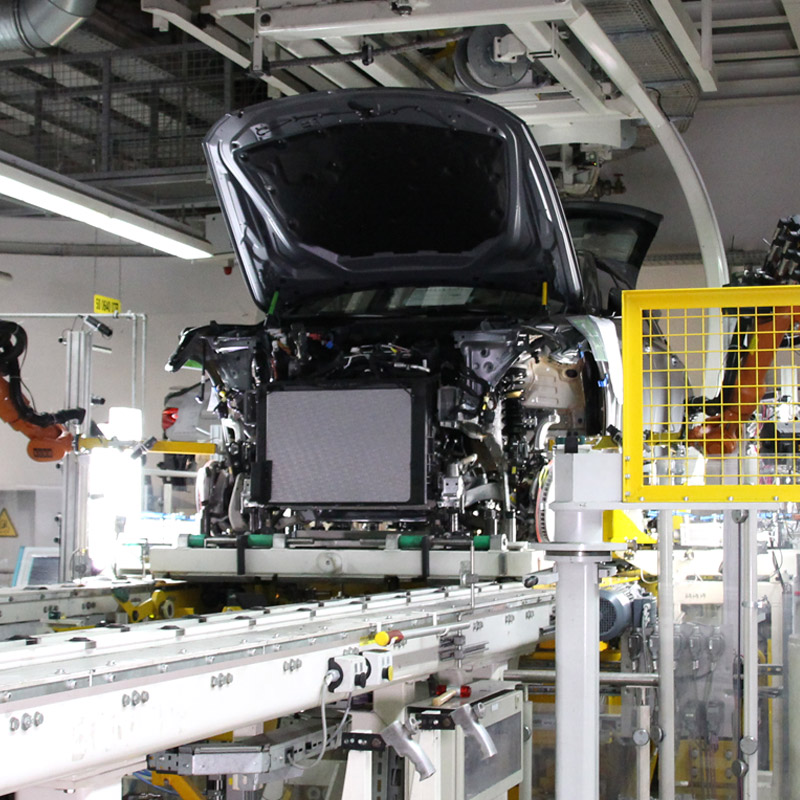

The ROFA Group stands for turnkey solutions from a single source in the areas of conveyor systems, automation technology, intralogistics, and special machine construction. We plan and implement new systems, modernizations, and conversions for existing systems for our customers, worldwide and in numerous industries. In times of disruptive change, we provide convincing and imaginative answers to the question of how productivity will continue to be possible in the future and how it can be implemented efficiently.

We transport the future.

COMPANIES AT A GLANCE

Dynamic Logistic Systems B.V. (Zevenaar, Netherlands), founded in 1999, is one of the top suppliers for internal material flow on the European market. Highly automated picking solutions, individual order picking and smart transport systems are among our particular strengths. With our efficient, flexible systems we help our customers, from various industries, to meet the ever increasing demands of the market environment. We flourished with the introduction of the Order Release Module (ORM), a smart, extremely fast combination of buffer solution and sorting system.

The demands placed on modern production facilities are becoming increasingly complex. With the establishment of ROFA Controls Romania S.R.L. (2012) we plan to meet this trend. Our experts support Group members in electromechanical construction of production systems, in final assembly of control technology and in mobile cabling systems. This enables us to offer our customers comprehensive and innovative solutions that help to achieve ambitious productivity goals.

ROFA GROUP IN NUMBERS

Our values

PRODUCT GROUPS

NEWS

The ROFA Group at LogiMAT 202629. January 2026We cordially invite you to visit us at LogiMAT, International Trade Fair for Intralogistics Solutions and Process Management. Meet the experts from ROFA Group, including BSS Bohnenberg GmbH, Dynamic Logistic Systems B.V., and ROFA INDUSTRIAL AUTOMATION AG. We look forward to welcoming you in person and presenting our latest products and systems.

When: March 24 – 26, 2026Where? Stuttgart Exhibition Center, Hall 1, Stand C50

We look forward to seeing you! [...]

The ROFA Group at LogiMAT 202629. January 2026We cordially invite you to visit us at LogiMAT, International Trade Fair for Intralogistics Solutions and Process Management. Meet the experts from ROFA Group, including BSS Bohnenberg GmbH, Dynamic Logistic Systems B.V., and ROFA INDUSTRIAL AUTOMATION AG. We look forward to welcoming you in person and presenting our latest products and systems.

When: March 24 – 26, 2026Where? Stuttgart Exhibition Center, Hall 1, Stand C50

We look forward to seeing you! [...] Change in Management at Morath Automatisierung GmbH7. January 2026Alexander Platter assumes sole Managing Director responsibility at Morath Automatisierung GmbH with immediate effect.

With more than ten years of international experience at ROFA’s U.S. location, he brings extensive expertise in automation, project management, and corporate leadership. He will leverage this experience to strategically develop Morath Automatisierung GmbH and strengthen the company’s long-term growth and sustainability.With this realignment, Morath Automatisierung GmbH continues to focus on continuity, competence, and the long-term, future-oriented development of the company.

For me, the team always comes first. It is especially important that every staff member feels treated fairly, enjoys coming to work, and performs their role with satisfaction and pride. Only in an environment where appreciation, trust, and collaboration are actively practiced can we achieve sustainable success together“, says Alexander Platter. [...]

Change in Management at Morath Automatisierung GmbH7. January 2026Alexander Platter assumes sole Managing Director responsibility at Morath Automatisierung GmbH with immediate effect.

With more than ten years of international experience at ROFA’s U.S. location, he brings extensive expertise in automation, project management, and corporate leadership. He will leverage this experience to strategically develop Morath Automatisierung GmbH and strengthen the company’s long-term growth and sustainability.With this realignment, Morath Automatisierung GmbH continues to focus on continuity, competence, and the long-term, future-oriented development of the company.

For me, the team always comes first. It is especially important that every staff member feels treated fairly, enjoys coming to work, and performs their role with satisfaction and pride. Only in an environment where appreciation, trust, and collaboration are actively practiced can we achieve sustainable success together“, says Alexander Platter. [...] 20 Years of ROFA China – A Valued Member of the ROFA Group Celebrates Its Anniversary30. October 2025Founded in August 2005, Rosenheimer (Beijing) Automation and Conveyance Technology Co. Ltd. has grown over the past 20 years into an essential member of the ROFA Group. With locations in Beijing and Chengde, ROFA China is now a leading provider of conveyor and material handling systems in the Chinese market.

Firmly rooted in China and backed by the international expertise of the ROFA Group, ROFA China delivers tailored technology solutions for modern industry. The company stands for top-tier quality, innovative technologies, and customer-focused service.

Over the past two decades, ROFA China has impressed with pioneering projects – from building the longest single EMS system in the automotive bodyshop, to introducing the first electric pallet conveyor in China’s tobacco industry, and independently realizing a major heavy-duty AGV project. Continuous expansion, the opening of new production facilities, and the development of proprietary patents highlight the company’s innovative strength and growth.

Today, ROFA China combines development, production, installation, commissioning and sales under one roof, while also offering technical consulting. With a highly qualified team, R&D centers at three locations and a process-oriented production approach, the company sets new standards in conveyor technology.

We warmly congratulate ROFA China on its 20th anniversary and look forward to many more years of shared innovation and success – true to the motto:

“We transport the future.”

Watch the anniversary video [...]

20 Years of ROFA China – A Valued Member of the ROFA Group Celebrates Its Anniversary30. October 2025Founded in August 2005, Rosenheimer (Beijing) Automation and Conveyance Technology Co. Ltd. has grown over the past 20 years into an essential member of the ROFA Group. With locations in Beijing and Chengde, ROFA China is now a leading provider of conveyor and material handling systems in the Chinese market.

Firmly rooted in China and backed by the international expertise of the ROFA Group, ROFA China delivers tailored technology solutions for modern industry. The company stands for top-tier quality, innovative technologies, and customer-focused service.

Over the past two decades, ROFA China has impressed with pioneering projects – from building the longest single EMS system in the automotive bodyshop, to introducing the first electric pallet conveyor in China’s tobacco industry, and independently realizing a major heavy-duty AGV project. Continuous expansion, the opening of new production facilities, and the development of proprietary patents highlight the company’s innovative strength and growth.

Today, ROFA China combines development, production, installation, commissioning and sales under one roof, while also offering technical consulting. With a highly qualified team, R&D centers at three locations and a process-oriented production approach, the company sets new standards in conveyor technology.

We warmly congratulate ROFA China on its 20th anniversary and look forward to many more years of shared innovation and success – true to the motto:

“We transport the future.”

Watch the anniversary video [...]