overhead conveyors

Produkte & Lösungen » Overhead conveyors » Electrified monorail systems

Electrified monorail systems - Flexible on the ceiling

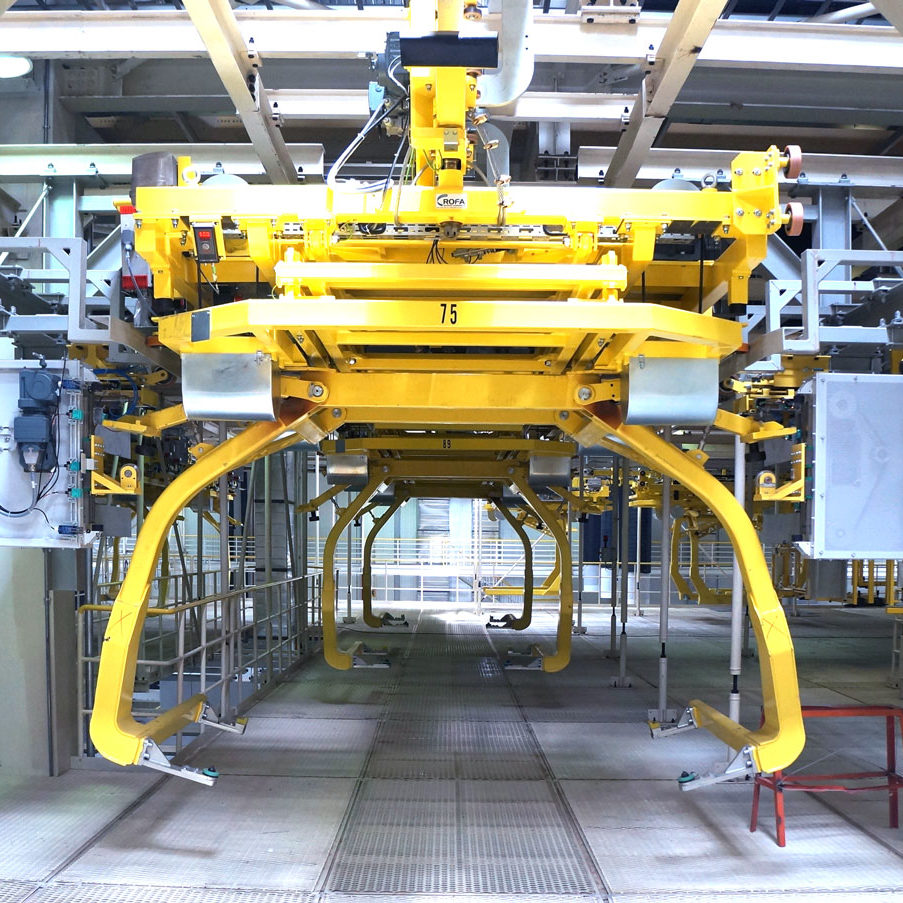

Electrified monorail systems KB240 (heavy-duty)

Electrified monorail system KB240 characteristics:

Load capacity: up to 10,000 kg

Speed: up to 60 m/min

Electrified monorail systems KB180 (C1 profile)

The electrified monorail system KB180 (EMS KB180) is an overhead conveyor system for in-plant material flow. It consists of independent vehicles that run freely on the track system. The running rail is suspended from the ceiling by brackets. This leaves the floor area under the track free for work and production purposes.

The track system allows any number of EMS vehicles to be operated continuously or in cycles. The modular design enables short assembly times as well as various configurations. Due to the climbing power established by the frictional bond, height differences of up to 5% are easy to overcome cost-effectively.

The plants work efficiently and rationally, at a low noise level and offer exact positioning accuracy and the highest degree of functionality. They can be individually adapted to any conveyor application and allow full compatibility with systems from other manufacturers built according to the same C1 standard.

Electrified monorail system KB180 characteristics

Load capacity: 1,500 kg

Speed: up to 150 m/min

Electrified monorail systems KB180 Heavy

The vehicles used for the electrified monorail system KB180 Heavy (EMS KB180 Heavy) are designed as trains of four. Accompanying conveyors can be integrated into the overhead for pallet transport, regardless of application (e.g. roller, chain, or belt conveyors). The double vehicle offers clear advantages in comparison to the conventional two-vehicle train. The doubled load enables increased plant throughput and thus system performance, while also resulting in fewer cycles at transfer points. Investment costs are lowered by economizing on electric cars and control components. This system also provides high speeds and acceleration with sturdy construction and low noise emission.

Thanks to its long service life, the electrified monorail system KB180 Heavy is ideal for interlinking different trades in in-plant material flow.

Electrified monorail system KB180 Heavy characteristics:

Load capacity: 3,000 kg

Speed: up to 120 m/min

Acceleration: 0.6 m/s²

electrified monorail system KB135 (light weight)

The electrified monorail system KB135 (EMS KB135) is the latest development in electrified monorail system technology from ROFA. Thanks to its compact structure with minimized height from the lower edge of the steel construction to the top of the crossbeam of 195 mm, it offers a huge range of possibilities for use with total loads of up to 300 kg. The modular design allows it to be assembled in a short time.

A clear advantage over the conventional electrified monorail systems KB180 and KB240 is the minimized height and weight. In some cases, the guide track (extruded aluminum profile 135 mm x 80 mm) can be directly attached to the steel construction. In terms of cost, savings of up to 30% were achieved in comparison to systems with the C1 profile.

Electrified monorail system KB135 characteristics:

Speed: up to 120 m/min

Acceleration: up to 0.6 m/s²

Speed can be infinitely adjusted with frequency converter